REVIEW OF OPERATIONS

Before dealing with actual operations of the Central Mint it might prove useful to briefly describe the kind of machinery used. The Mint had its own power plant with two 300 kw. Westinghouse turbogenerators. The mot or power voltage was 440, while 220 volt was used for lighting purposes. The monthly consumption of power was about 120,000 kw. hours. Steam for turbines, minting and heating was supplied by four hand-fired water tube horizontal boilers, of which one was always kept in reserve; steam pressure 170 lbs. per square inch. Each boiler had a normal capacity of 4,600 lbs per hour, requiring 700 to 800 lbs of coal per hour when generating steam up to normal capacity. Gas furnaces were used for melting and annealing. Gas was supplied by three units of Smith 108 type F hand-operated gas producers, the normal capacity of each having been 25,000 cubic feet per hour. The calorific value of the gas was about 140 B.T.U. per cubic foot. Each unit required about 400 lbs of coal per hour under normal operations. When it was found that gas of higher calorific value should be used the Mint substituted its own gas producers by gas with a calorific value of 440 B.T.U supplied by the Shanghai Gas Company.

Before dealing with actual operations of the Central Mint it might prove useful to briefly describe the kind of machinery used. The Mint had its own power plant with two 300 kw. Westinghouse turbogenerators. The mot or power voltage was 440, while 220 volt was used for lighting purposes. The monthly consumption of power was about 120,000 kw. hours. Steam for turbines, minting and heating was supplied by four hand-fired water tube horizontal boilers, of which one was always kept in reserve; steam pressure 170 lbs. per square inch. Each boiler had a normal capacity of 4,600 lbs per hour, requiring 700 to 800 lbs of coal per hour when generating steam up to normal capacity. Gas furnaces were used for melting and annealing. Gas was supplied by three units of Smith 108 type F hand-operated gas producers, the normal capacity of each having been 25,000 cubic feet per hour. The calorific value of the gas was about 140 B.T.U. per cubic foot. Each unit required about 400 lbs of coal per hour under normal operations. When it was found that gas of higher calorific value should be used the Mint substituted its own gas producers by gas with a calorific value of 440 B.T.U supplied by the Shanghai Gas Company.

In the beginning extensive training had to be given to the workmen, of whom there were 400; the Mint’s technical and administrative staff comprised 150 members. After five months careful training of the workers a daily output of $200,000 was reached.

Mr. Lu Hsue-pu was appointed director in April, 1933; aided by Mr.R.J.Grant (late director of all Mints in the United States), notable achievements were recorded. With the active assistance of the three Chinese department heads (assaying, melting andcoining), who had been trained at the Philadelphia Mint, the Shanghai coinage plant continued on the way to progress. For instance, the speed of the stamping presses was increased from 76 to 90 coins per minute, while the automatic weighing machines handled 120 coins, compared with previously 100 per minute. After six months trial the Central Mint turned out 250,000 dollar coins per working day of ten hours.

The National Government Central Mint, Shanghai, stood on its own grounds of about 100 mou of land. After passing through the Essay Department one entered the melting and refining section, to which was adjoined the large and modern silver vault. The Silver ingots, after analysis, were then taken to the Rolling Room, where they were rolled into the standard thickness of the dollar. The long silver strips were then sent to the punching machines. Thereafter the good blanks were weighed. Before the dye was stamped on, the blanks had to be heated in an annealing furnace and thereafter washed, dryed and milled. Thereupon the final process took place in the stamping presses, the obverse and the reverse being stamped on the coins simultaneously under a pressure of 160 tons. The finished dollars then had to pass through automatic weighing machines, which separated the too heavy and the too light coins from the standard pieces, weighing 412 troy grains with a tolerance of 1.2 grains either way. Thereafter the good coins were packed into cases of 5,000 dollars.

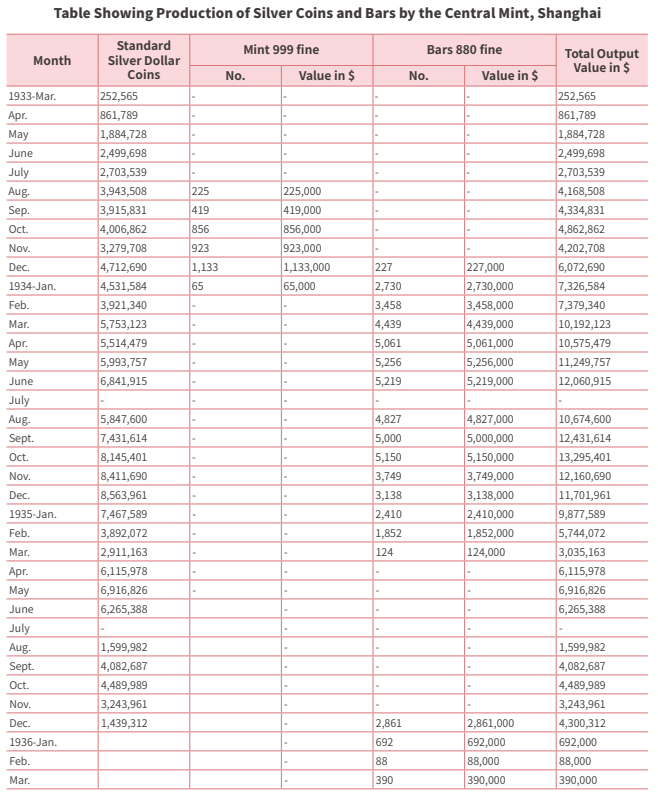

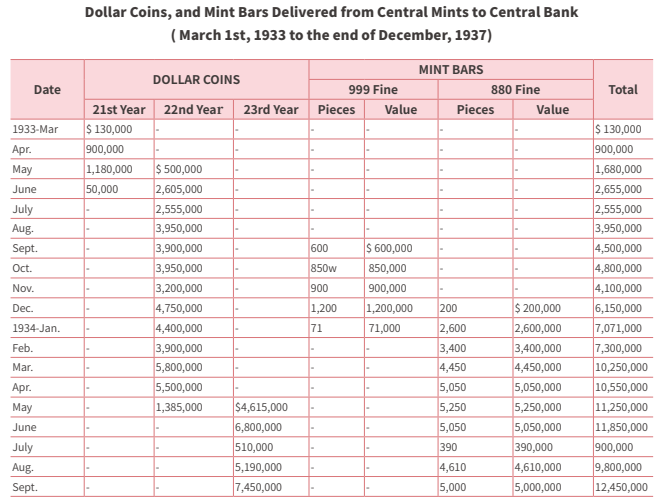

The abolition of the tael created a great demand for the silver dollar. As the Central Mint was not enabled to supply sufficient coins, it was decided to produce mint bars "A" with a fineness of 999/1000ths, to be followed by mint bars "B" of a fineness of 880/1000ths.18 The contents of these bars represented exactly the fine silver contained in a thousand new standard silver dollars.

All the dies were made by the Mint at Philadelphia. On an average the Central Mint has been using 40 dollar dies per month. After having struck 208,000 coins (average) the dies were worn out and had to be discarded.

For the opening operations American bar silver was used for the manufacture of silver dollars. But due to the small size of stocks available this basic material was exhausted by the end of 1933; slightly over six million troy ounces of bar silver 0.999 fine were consumed by the Central Mint for its initial operations. From May, 1933, onward, sycee silver was used by the Mint almost exclusively for the manufacturer of standard dollars.

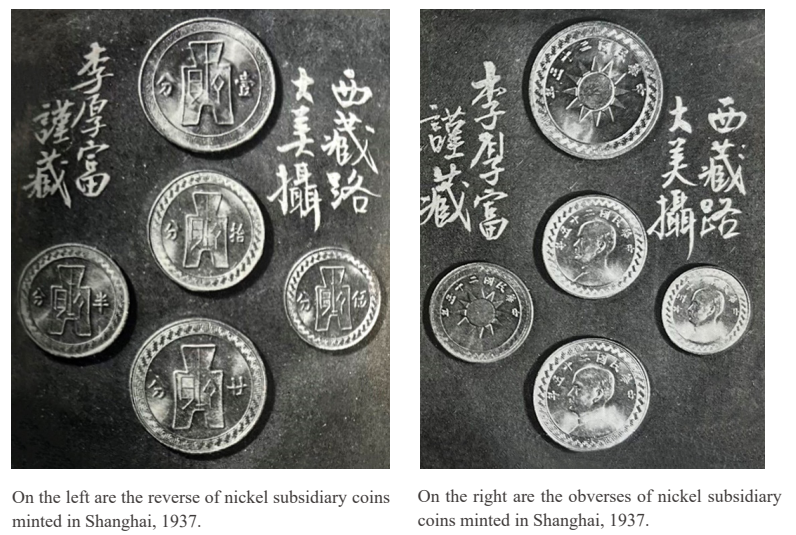

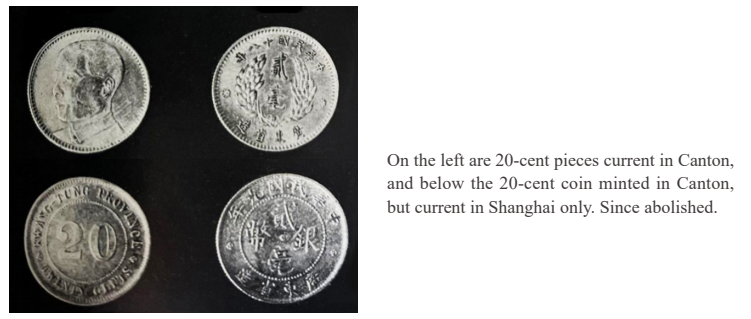

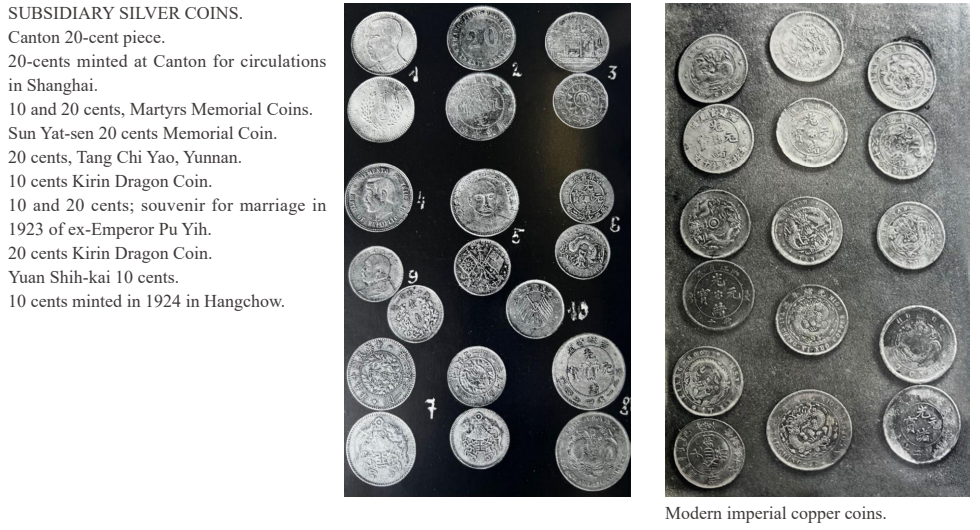

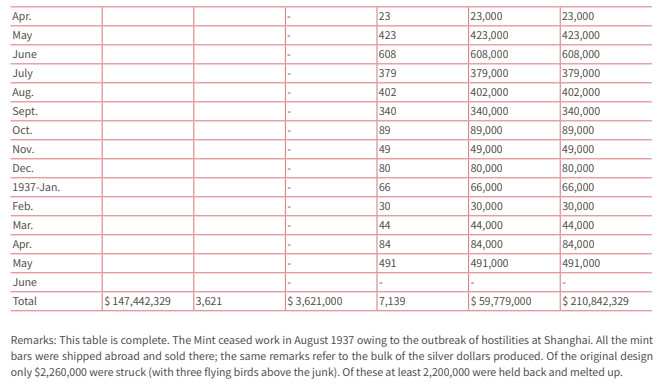

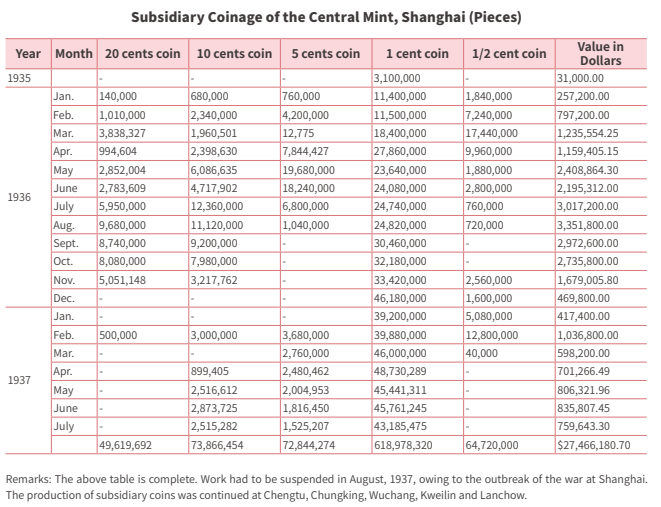

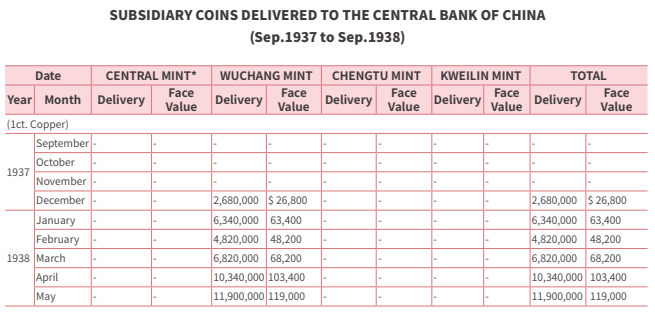

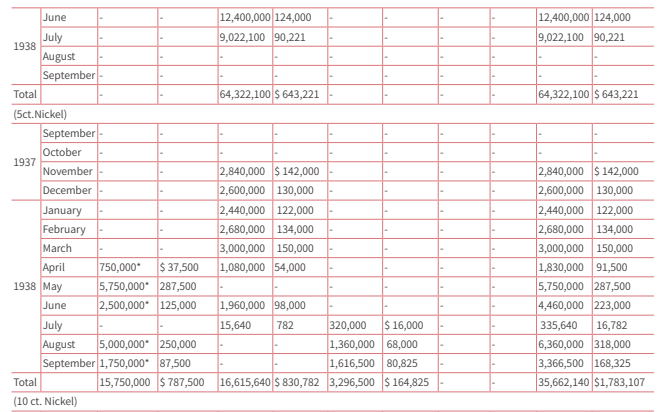

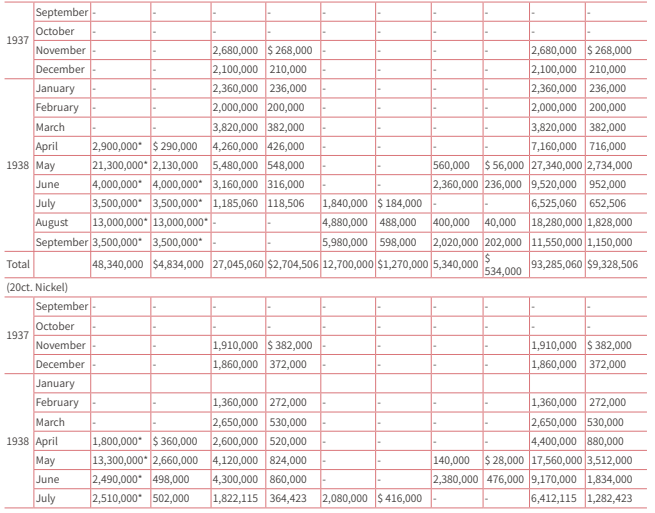

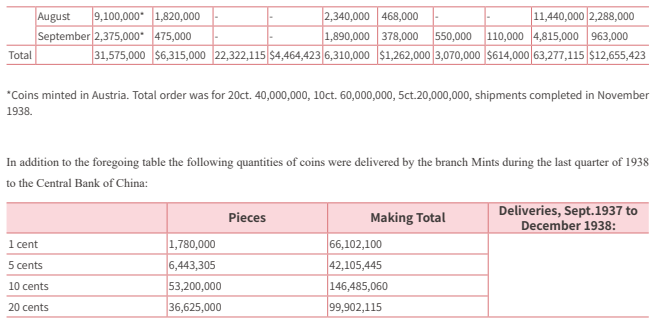

From March to June, 1933, altogether 2,260,000 silver dollars were produced, showing the bust of Dr.Sun Yat-sen on the obverse, the typical junk, over which flew three sea gulls and the rising sun on the reverse. Soon objections were raised against the flying birds, and the rising sun so that the stock of new coins was condemned and re-minted; about 50,000 of the coins with the original design remained in circulation. From May, 1933, onward a dollar with the same design, but minus the flock of birds, was produced by the Shanghai Mint. The coins dated (in Chinese) "21st Year of the Republic" were really struck in 1933; those of the 22nd Year in 1934; those of the 23rd Year in 1935-1937.It was on December 21, 1935, that the first one-cent, full-value copper coin was produced by the Central Mint in Shanghai, though none were delivered in 1935 to the Central Bank of China. From January 1936, onward the Mint turned out quantities of subsidiary coins, viz.1/2 and 1 cent in copper, and 5, 10, and 20 cents in nickel.

All these new coins rapidly gained popular favour, doing away with the daily fluctuations of the varied output of “small coin” coppers. The nickel coins were dated “25th Year of the Republic.”*

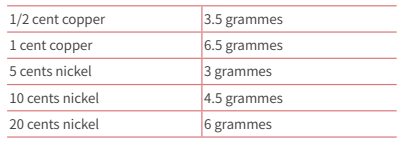

According to the currency law of November 3, 1935, the new copper coins were to contain 95 per cent of copper and 5 per cent of tin-zinc alloy. The nickel coins consisted of 100 per cent pure nickel, the blanks being imported from America. The legal weight for the new coins was fixed as follows:

Mr. Lu Hsue-pu was appointed director in April, 1933; aided by Mr.R.J.Grant (late director of all Mints in the United States), notable achievements were recorded. With the active assistance of the three Chinese department heads (assaying, melting andcoining), who had been trained at the Philadelphia Mint, the Shanghai coinage plant continued on the way to progress. For instance, the speed of the stamping presses was increased from 76 to 90 coins per minute, while the automatic weighing machines handled 120 coins, compared with previously 100 per minute. After six months trial the Central Mint turned out 250,000 dollar coins per working day of ten hours.

The National Government Central Mint, Shanghai, stood on its own grounds of about 100 mou of land. After passing through the Essay Department one entered the melting and refining section, to which was adjoined the large and modern silver vault. The Silver ingots, after analysis, were then taken to the Rolling Room, where they were rolled into the standard thickness of the dollar. The long silver strips were then sent to the punching machines. Thereafter the good blanks were weighed. Before the dye was stamped on, the blanks had to be heated in an annealing furnace and thereafter washed, dryed and milled. Thereupon the final process took place in the stamping presses, the obverse and the reverse being stamped on the coins simultaneously under a pressure of 160 tons. The finished dollars then had to pass through automatic weighing machines, which separated the too heavy and the too light coins from the standard pieces, weighing 412 troy grains with a tolerance of 1.2 grains either way. Thereafter the good coins were packed into cases of 5,000 dollars.

The abolition of the tael created a great demand for the silver dollar. As the Central Mint was not enabled to supply sufficient coins, it was decided to produce mint bars "A" with a fineness of 999/1000ths, to be followed by mint bars "B" of a fineness of 880/1000ths.18 The contents of these bars represented exactly the fine silver contained in a thousand new standard silver dollars.

All the dies were made by the Mint at Philadelphia. On an average the Central Mint has been using 40 dollar dies per month. After having struck 208,000 coins (average) the dies were worn out and had to be discarded.

For the opening operations American bar silver was used for the manufacture of silver dollars. But due to the small size of stocks available this basic material was exhausted by the end of 1933; slightly over six million troy ounces of bar silver 0.999 fine were consumed by the Central Mint for its initial operations. From May, 1933, onward, sycee silver was used by the Mint almost exclusively for the manufacturer of standard dollars.

From March to June, 1933, altogether 2,260,000 silver dollars were produced, showing the bust of Dr.Sun Yat-sen on the obverse, the typical junk, over which flew three sea gulls and the rising sun on the reverse. Soon objections were raised against the flying birds, and the rising sun so that the stock of new coins was condemned and re-minted; about 50,000 of the coins with the original design remained in circulation. From May, 1933, onward a dollar with the same design, but minus the flock of birds, was produced by the Shanghai Mint. The coins dated (in Chinese) "21st Year of the Republic" were really struck in 1933; those of the 22nd Year in 1934; those of the 23rd Year in 1935-1937.It was on December 21, 1935, that the first one-cent, full-value copper coin was produced by the Central Mint in Shanghai, though none were delivered in 1935 to the Central Bank of China. From January 1936, onward the Mint turned out quantities of subsidiary coins, viz.1/2 and 1 cent in copper, and 5, 10, and 20 cents in nickel.

All these new coins rapidly gained popular favour, doing away with the daily fluctuations of the varied output of “small coin” coppers. The nickel coins were dated “25th Year of the Republic.”*

According to the currency law of November 3, 1935, the new copper coins were to contain 95 per cent of copper and 5 per cent of tin-zinc alloy. The nickel coins consisted of 100 per cent pure nickel, the blanks being imported from America. The legal weight for the new coins was fixed as follows:

The obverse of the copper coins contains within an outer circle the reproduction of ancient spade money and the denomination in Chinese. The reverse has the Kuomintang emblem in the centre and above within a half-circle the Chinese characters for “Chinese Republic 25th Year, (or 26th Year). The nickel coins show on the obverse the profile of Dr. Sun Yat-sen facing left, and above in a half-circle the inscription “Chinese Republic 25th Year”(1936). The reverse of the nickel coins is identical with the obverse of the copper coins, namely a replica of the old spade money and the denomination.

Since the abolition of silver as the basis of Chinese currency the production of silver dollars ceased entirely at the close of 1935. Thereafter only copper and subsidiary nickel coins were to be struck. A moderate quantity of silver bars “B” continued to be cast.

Mr. Jian H. Chen, who had been acting concurrently as Director of the Central Mint, handed over to Mr. T.P. Hsi in April, 1937.

Due to the outbreak of Sino-Japanese hostilities in August of 1937 the machinery of the Central Mint of Shanghai was dismantled and transported into the interior of the country. It was set up in other places, like Kweilin, Chungking, Chengtu, Wuchang and Lanchow, which became regional branches of the Central Mint.

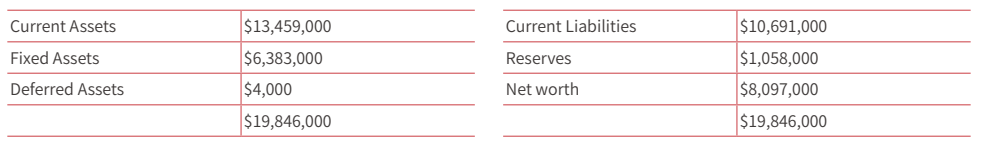

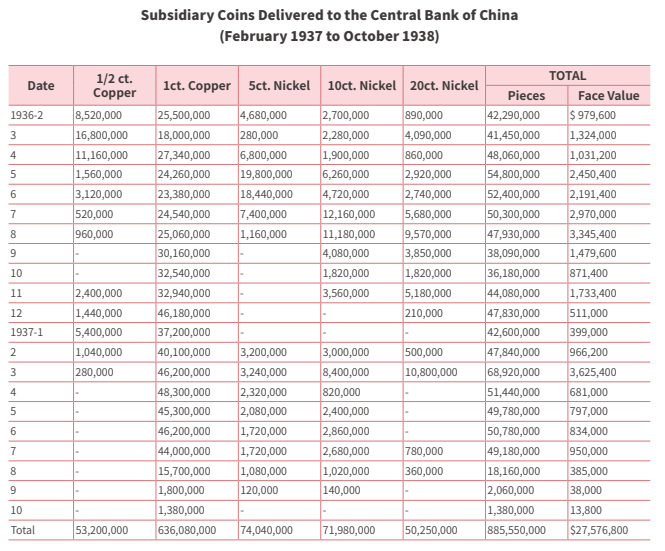

According to the balance sheet published by the Central Mint of Shanghai on March 31, 1937, its net worth then was $8,097,000. Although the Mint operated at a profit, same was very moderate. The net worth represented assets which the Government had paid for and so to say written off. The principal figures, condensed according to groups, on March 31, 1937, are as follows:

* Including 270 pieces, being the balance formerly withdrawn from bank, which were again delivered to the Central Bank in December 1935 due to discontinuance of turning into coins.

After December 1937, no more silver dollars were minted and none were subsequently delivered. Therefore the foregoing list is complete and final.

After December 1937, no more silver dollars were minted and none were subsequently delivered. Therefore the foregoing list is complete and final.

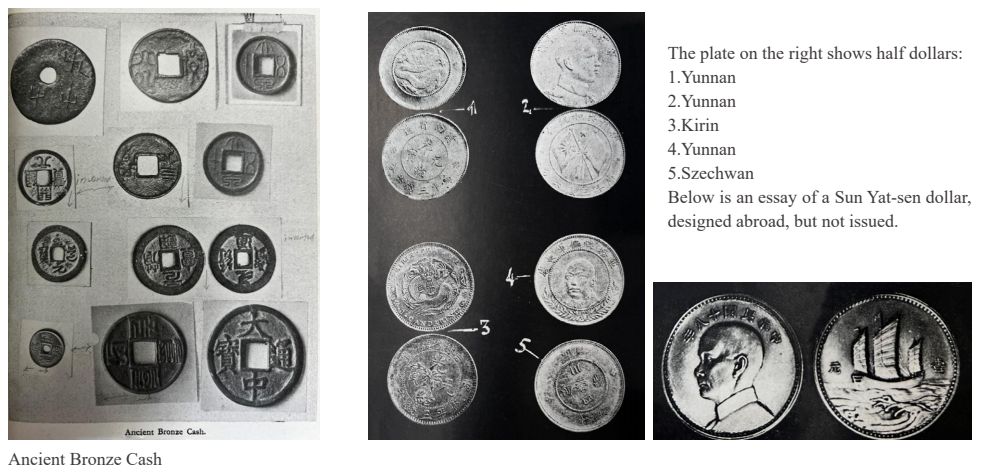

Republican copper coins of 1 and 2 cents value.

Since replaced by a new big money 1/2 and 1 cent piece

DOLLAR COINS:

1. Silver Yen.

2. British dollar.

3. Specimen of a Sun Yat Sen

$, never issued.

4. Saigon piastre.

5. Szechuan dollar.

6. Singapore $

1. Silver Yen.

2. British dollar.

3. Specimen of a Sun Yat Sen

$, never issued.

4. Saigon piastre.

5. Szechuan dollar.

6. Singapore $